Strong Performance in Quality Air

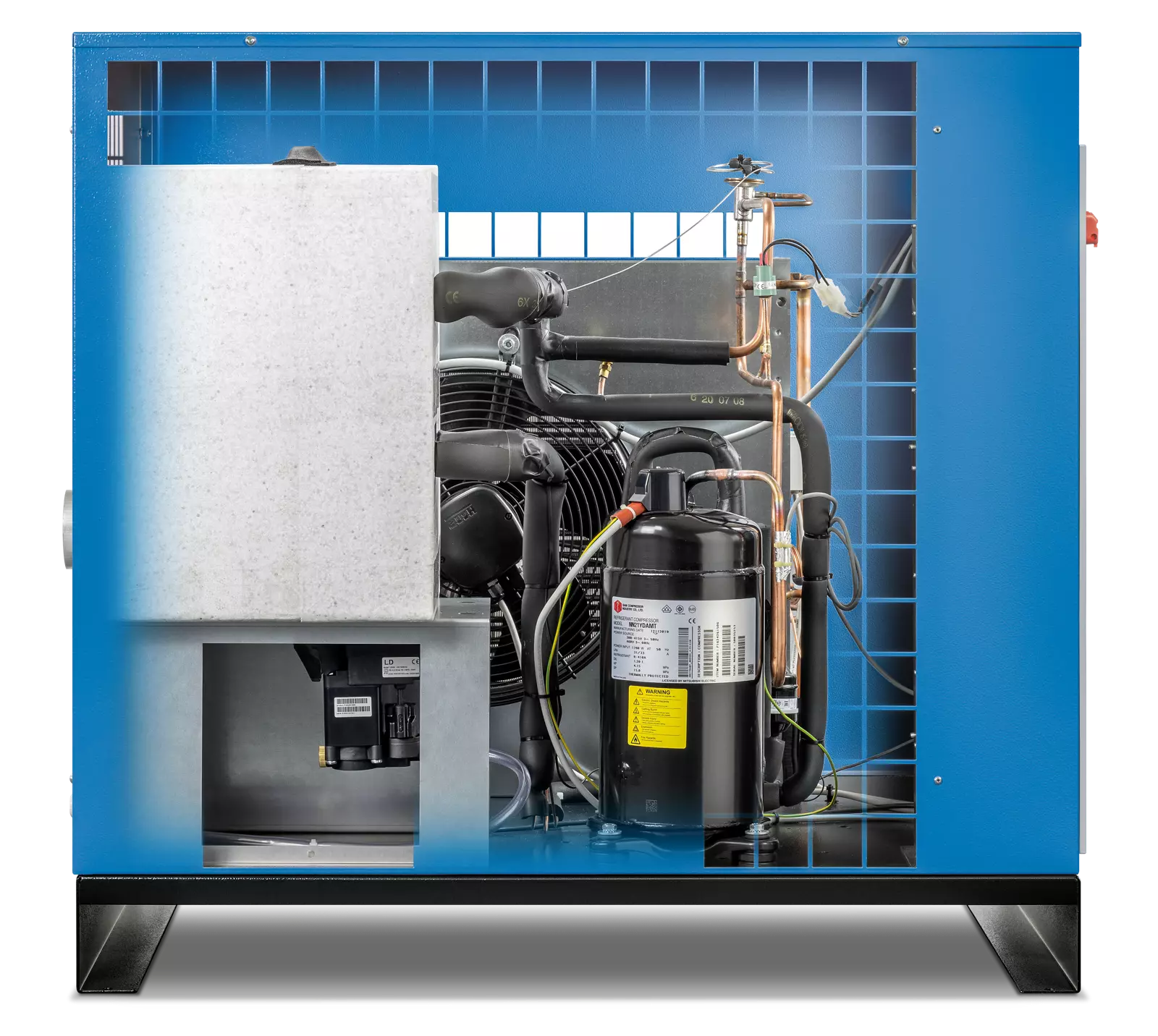

Condensate Management Technology

The intelligent condensate drain is fitted with sensors that remove water efficiently, without comprising the quality of your compressed. Thanks to this specific technology, your system works quietly and efficiently while allowing you to save on your energy consumption.

Also, waste is limited since this system only removes water.

FULL OF FEATURES

Why Choose the DW range?

This is THE solution to protect efficiently your final products from corrosion and contamination. The DW refrigerant dryers offer a streamlined design that combines solid performance, efficiency and user-friendliness. Their compact form allows easy integration into various setups and are built to ensure your equipment stays secure by eliminating moisture. Thanks to their energy-efficient features, you’ll also lower operational costs, making it a wise investment for your business.

Technical data

| Model | Motor Power (kW) | Max. Pressure (bar) | Capacity (m³/h)* | Noise Level (dBa) |

|---|---|---|---|---|

| DW 2 | 130 | 16 | 21 | 19 |

| DW 144 | 3500 | 14 | 1440 | 230 |

| DW 720 | 12180 | 14 | 7200 | 900 |

| DW 31 G | 933 | 14 | 312 | 64 |

| DW 46 G | 1276 | 14 | 462 | 92 |

| DW 108 G | 2629 | 14 | 1080 | 176 |